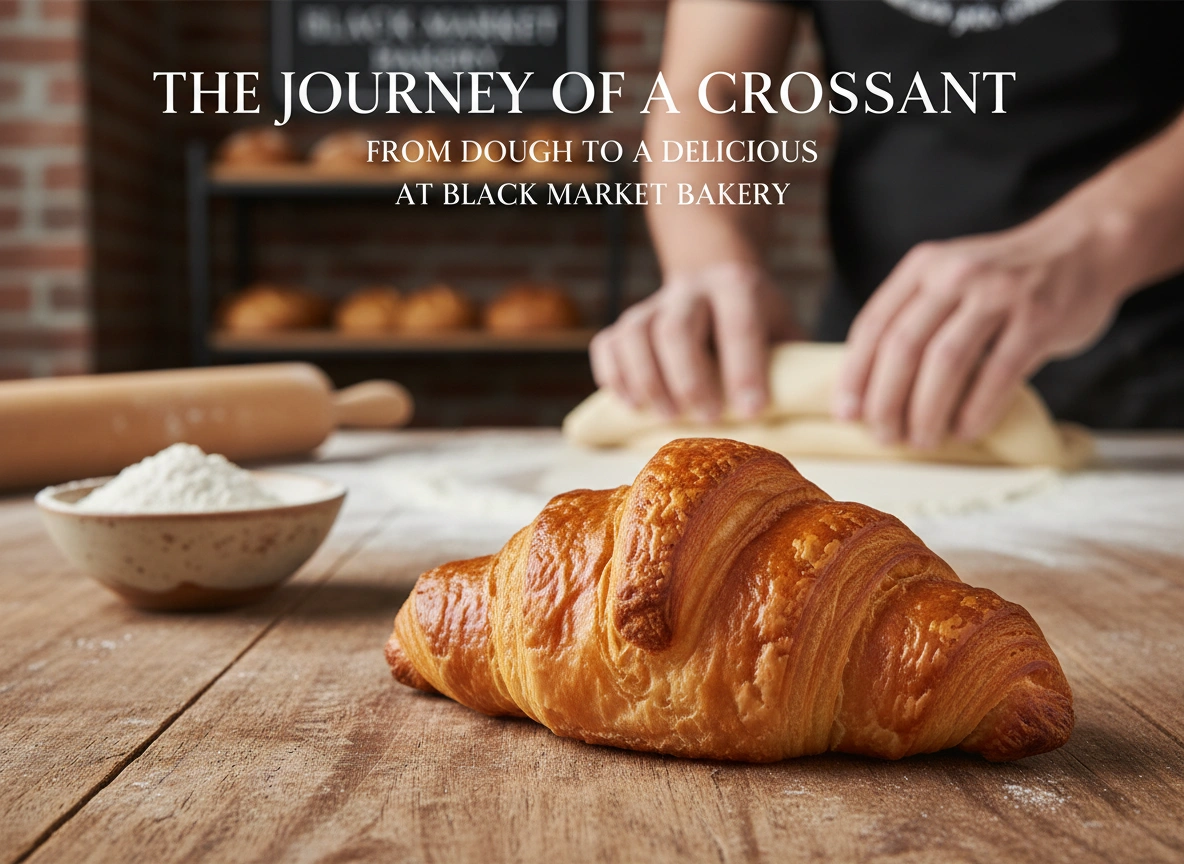

That first bite of a truly exceptional croissant is a moment of pure magic. A delicate, paper-thin crust gives way with a satisfying shatter, revealing a honeycomb of airy, buttery layers that practically melt in your mouth. It’s a simple pleasure, yet creating it is anything but. At Black Market Bakery, the journey of a croissant is a multi-day testament to patience, precision, and passion. It’s a process that transforms humble ingredients—flour, butter, water, and yeast—into an edible work of art.

This is not a story of shortcuts or industrial mixers churning out pastries by the thousand. It is a story of craftsmanship, where human hands and expert knowledge guide every step. We’ll pull back the curtain on the meticulous process behind Black Market Bakery’s beloved croissants, exploring the science and soul baked into every golden crescent. From the initial mixing of the dough to the final, fragrant emergence from the oven, you’ll discover why these pastries are so much more than just a breakfast treat.

The Foundation: Building the Perfect Dough

The journey begins not with a flurry of activity, but with careful consideration. The soul of any great croissant lies in its dough, known as the détrempe. This simple mixture of high-protein flour, water, yeast, sugar, and salt sets the stage for everything that follows. The quality of these foundational ingredients is non-negotiable at Black Market Bakery.

Selecting Superior Ingredients

The bakers at Black Market Bakery understand that you can’t create a superior product from inferior components. The flour is chosen for its specific protein content, which is crucial for developing the gluten structure needed to support the countless layers of butter. This structure must be strong enough to trap the steam released during baking, creating the croissant’s signature airy interior.

The butter is perhaps the most celebrated ingredient. The bakery uses a high-fat, European-style butter. Unlike standard American butter, which has a higher water content, this butter is more pliable and has a richer flavor. Its plasticity is key; it needs to spread evenly without melting into the dough or becoming brittle and breaking during the lamination process. This single choice dramatically impacts the final flavor and texture.

The Gentle Art of Mixing

Once the ingredients are selected, the détrempe is mixed. The process is deceptively simple. The goal is to combine the ingredients until they just come together, without overworking the dough. Over-mixing would develop the gluten too early, resulting in a tough, bready croissant rather than a light and tender one. The bakers use a gentle hand, respecting the integrity of the ingredients.

After mixing, the dough is given its first, long rest. This cold fermentation period, often lasting overnight in a carefully controlled environment, is where the magic begins. The slow, cool proofing allows complex flavors to develop. The yeast works its magic at a snail’s pace, creating subtle, nuanced notes that can’t be rushed. This resting phase also relaxes the gluten, making the dough more extensible and ready for the critical next step: lamination.

Lamination: The Art of Creating Layers

Lamination is the heart of croissant making. It’s the process of folding a block of cold butter into the dough over and over again to create hundreds of alternating layers of dough and butter. This is where technical skill and physical effort converge.

Encasing the Butter

The process starts with a perfectly chilled slab of butter and the rested détrempe. The bakers at Black Market Bakery expertly roll the dough into a square, placing the butter block in the center. The dough is then folded over the butter like an envelope, completely encasing it. This package is called a pâton. It’s crucial that the butter is sealed in perfectly; any exposed butter would melt out during baking, ruining the flaky structure.

The temperature of both the dough and the butter must be just right. If the butter is too cold, it will shatter when rolled. If it’s too warm, it will blend into the dough. The bakers work quickly and efficiently in a temperature-controlled room, using their experience to feel when the components are at the ideal state.

The Turns: Building the Structure

Next comes the series of “turns.” The pâton is carefully rolled out into a long rectangle and then folded. There are different types of folds, but a common one is the “letter fold,” where the dough is folded into thirds, just like a business letter. This single action triples the number of layers.

After the first turn, the dough is wrapped and returned to the refrigerator to rest. This rest period is vital. It allows the gluten to relax again, preventing it from resisting the rolling pin and tearing. It also ensures the butter remains solid. This process of rolling, folding, and resting is repeated several times over many hours, sometimes even spanning a second day.

With each turn, the layers of butter become progressively thinner, separated by equally thin layers of dough. The final product can have hundreds of individual layers, though they are too thin to be seen by the naked eye. It’s this intricate architecture that will create the croissant’s iconic honeycomb interior.

Shaping and Proofing: The Final Transformation

After the final rest, the laminated dough is ready to be transformed into its familiar crescent shape. This stage requires a delicate touch and an eye for uniformity.

Cutting and Rolling with Precision

The chilled dough is gently rolled out one last time into a large, thin sheet. The bakers then use specialized cutters or sharp knives to slice the dough into long, slender triangles. The precision here is important for ensuring each croissant is a consistent size and weight, which in turn ensures they all bake evenly.

Each triangle is then carefully stretched to elongate it before being rolled up, starting from its wide base. The motion is deliberate but gentle, creating the classic crescent shape with its distinct “shoulders.” Some croissants, like the pain au chocolat, are shaped differently to accommodate their delicious fillings, but the principle remains the same. The shaped croissants are placed on baking sheets, leaving ample space between them. They are now ready for their final rise, or proofing.

The Final Proof: A Test of Patience

Proofing is the stage where the yeast becomes active again, producing carbon dioxide that inflates the dough. This is an incredibly sensitive step. The proofing environment must be warm and humid enough to encourage the yeast, but not so warm that the butter layers melt and leak out. A “melt-out” at this stage would be disastrous, resulting in a dense, greasy pastry.

The bakers at Black Market Bakery monitor the proofing croissants with a watchful eye. It can take a few hours for them to double in size, becoming visibly puffy and delicate. They jiggle like gelatin when the tray is gently shaken—a key indicator that they are perfectly proofed and ready for the oven. Just before baking, they receive a gentle egg wash, which gives them their beautiful golden sheen.

The Bake: A Fiery Finale

The final step is the bake. The proofed croissants are placed into a hot, convection oven. The initial blast of high heat causes “oven spring”—the water in the dough and butter turns to steam, explosively puffing up the layers and creating the croissant’s airy pockets. The convection fans ensure that the heat circulates evenly, browning the pastries to a perfect, crisp gold.

The aroma that fills the bakery during this time is intoxicating—a rich, nutty scent of browning butter and caramelized sugar. The bakers know precisely when to pull them from the oven, judging by color and texture. The result is a tray of perfectly golden, impossibly light croissants. They are cooled on racks, their delicate crust crackling softly as they settle.

From the first mix of the détrempe to the moment they are placed in the pastry case, the creation of a Black Market Bakery croissant is a three-day journey. It’s a process that honors tradition while demanding perfection. It’s a dance of temperature and time, of strength and gentleness. More than anything, it is a labor of love, and you can taste it in every single bite.

Please click here for more info.